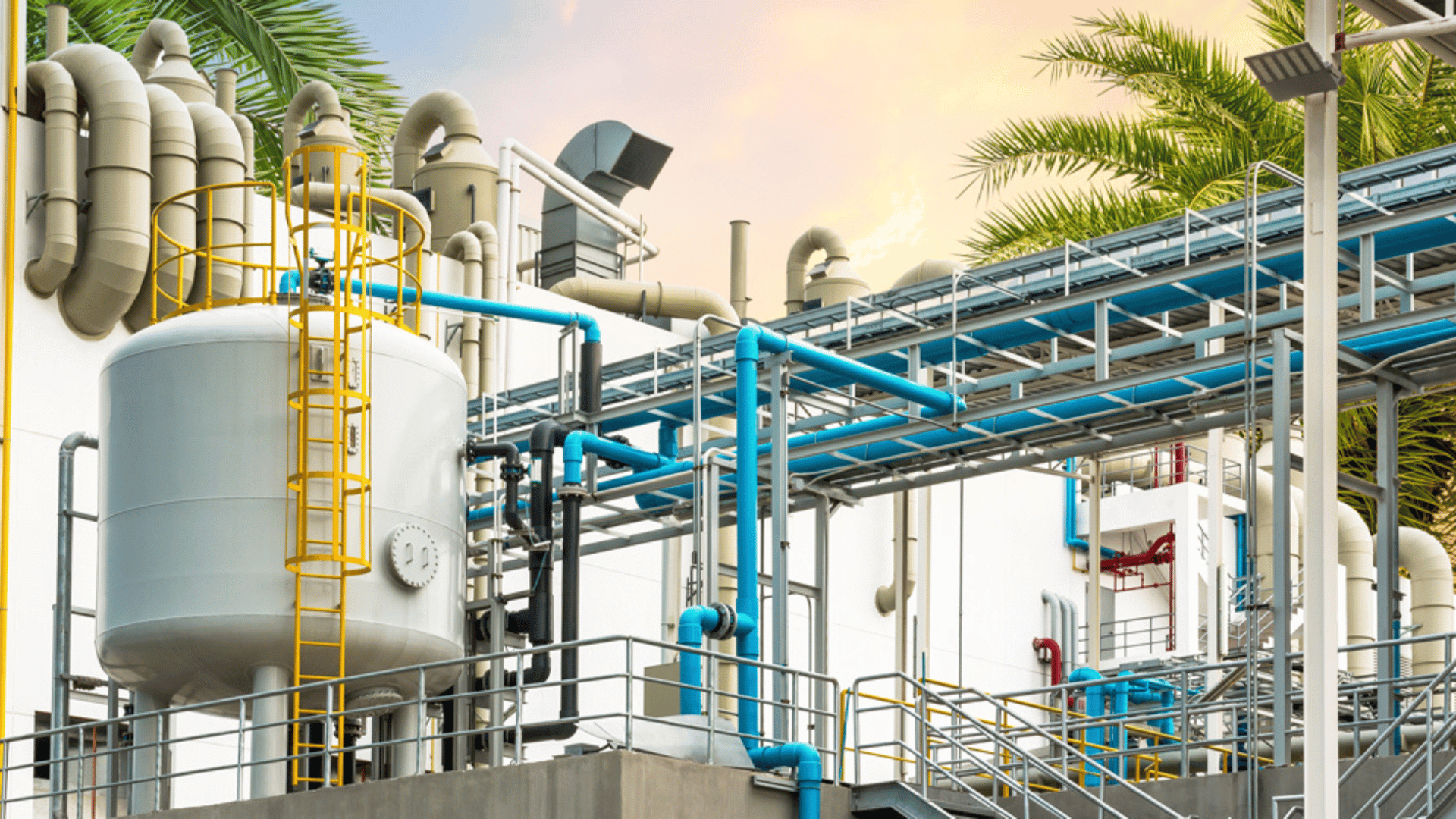

Zero Liquid Discharge Plant ZLD Plant

Complete Water Recovery. Zero Wastewater Discharge.

Our Zero Liquid Discharge (ZLD) Plant is a cutting-edge wastewater treatment solution designed to achieve maximum water recovery while eliminating liquid waste discharge. Ideal for industries facing strict environmental regulations, our ZLD systems help businesses meet sustainability goals by turning waste into reusable water and minimizing ecological impact.

Applications:

- Textile & Dyeing Units

- Power Plants

- Petrochemical & Refinery Industries

- Pharmaceutical Manufacturing

Food & Beverage Processing

Why Choose Our Zero Liquid Discharge Plant ZLD?

- Tailored turnkey solutions

- Proven performance and industry expertise

- Reduced water footprint

- Regulatory compliance made simple

What is a Zero Liquid Discharge Plant ZLD?

A Planta de Zero Liquid Discharge (ZLD) es un avanzado sistema de tratamiento de residuos diseñado para eliminar liquid residuos provenientes de procesos industriales. The main goal of a ZLD plant is to recover and recycle almost all wastewater, ensuring that no liquid effluent is discharged into the environment.

ZLD tecnología comprende técnicas de tratamiento tales como filtration, reverse osmosis, evaporation y crystallization. These processes work together to separate clean water from contaminants, enabling industries to reuse treated water within their operations and dispose of only solid waste safely.

ZLD systems are especially critical for industries operating in water-scarce regions or those bound by strict environmental regulations. By implementing a ZLD plant, companies protect natural resources, achieve long-term cost savings, and ensure compliance with local pollution control norms.

Whether you’re in the textile, chemical, power, or pharmaceutical sector, a ZLD plant helps your business become more eco-friendly, efficient, and future-ready.

How Zero Liquid Discharge Plant ZLD Systems Help Industries Achieve Sustainability

Zero Liquid Discharge (ZLD) systems play a vital role in helping industries reduce their environmental footprint and promote long-term sustainability. By recovering and reusing wastewater, ZLD technology ensures that no harmful liquid waste is released into the environment — a major step toward responsible resource management.

With growing concerns around water scarcity and pollution, industries are under increasing pressure to adopt sustainable practices. ZLD plants offer a practical solution by enabling:

Maximum Water Recovery: Treated water is purified and reused within industrial processes, reducing dependency on freshwater sources.

- Elimination of Liquid Effluent: No wastewater is discharged into soil or water bodies, minimizing ecological damage and regulatory risks.

- Compliance with Environmental Laws: ZLD systems help industries meet stringent pollution control board norms and avoid penalties or shutdowns.

- Waste Minimization: Solid waste generated from the treatment process can be safely handled or repurposed, reducing landfill impact.

- Improved Corporate Image: Demonstrating a commitment to environmental stewardship enhances brand reputation and stakeholder trust.

The Zero Liquid Discharge Plant ZLD Process: Step-by-Step Overview

The Zero Liquid Discharge (ZLD) process is a multi-stage treatment method that ensures complete elimination of liquid waste from industrial effluents. Each stage of the ZLD process is designed to separate water from contaminants and convert wastewater into reusable resources and manageable solid waste.

How the ZLD process works:

- Pre-Treatment

En esta etapa inicial, el wastewater es filtrado para eliminar suspended solids, oils, and particles de gran tamaño. Chemical dosing may be applied to neutralize pH levels and prepare the water for further treatment.

- Primary Treatment (RO Filtration)

The pre-treated water passes through high-efficiency Reverse Osmosis (RO) membranes. This stage removes dissolved salts, heavy metals, and organic compounds, allowing the recovery of up to 75–85% of clean water.

- Evaporation

The RO reject water, which contains high concentrations of dissolved solids, is sent to evaporators. The heat is utilized to vaporize the water, distinguishing it from the impurities dissolved. The vapor is distilled for reutilización.

- Crystallization

The concentrated brine left after evaporation is sent to crystallizers, where remaining salts and solids are further separated and crystallized into a dry, disposable form.

- Solid Waste Management

The solid byproducts (like salt crystals or sludge) are collected, dried, and safely disposed of or repurposed, depending on their composition and environmental guidelines.

- Water Reuse

The recovered clean water is redirected for use in industrial processes, cooling systems, or utility operations, drastically reducing freshwater intake.

Ventajas de Implementar a Planta de Dispersión Líquida Sin Límite

Implementing a Zero Liquid Discharge Plant ZLD Plant offers a wide range of advantages for industries that are committed to environmental responsibility and operational efficiency. Beyond compliance, ZLD systems help conserve water, reduce costs, and support long-term sustainability goals.

Key Benefits:

✅ Complete Environmental Compliance Zero Liquid Discharge Plant ZLD systems ensure that no liquid waste is discharged into natural water bodies, helping industries meet even the strictest regulations set by pollution control authorities.

💧 Maximum Water Reuse By recovering and recycling up to 95% of wastewater, Zero Liquid Discharge Plant ZLD plants significantly reduce the need for fresh water, easing the strain on local water supplies.

♻️ Reduced Environmental Impact With no harmful discharge entering the environment, ZLD systems help protect local ecosystems and groundwater from contamination.

💰 Lower Long-Term Operational Costs Although the initial investment can be higher, ZLD systems reduce ongoing costs related to water sourcing, effluent disposal, and environmental penalties.

🏭 Improved Operational Efficiency Clean, recycled water can be reused within industrial processes, improving overall productivity and reducing downtime due to water shortages.

🌱 Enhanced Corporate Image Adopting a ZLD solution showcases your company’s commitment to sustainability, which is increasingly important to investors, partners, and customers.

📊 Future-Ready Infrastructure ZLD plants future-proof your facility against tightening water usage laws, rising freshwater costs, and growing environmental awareness.

ZLD Plant Installation and Maintenance Services

Installing a Zero Liquid Discharge Plant ZLD requires more than just equipment — it demands expert planning, precision engineering, and ongoing technical support to ensure optimal performance. We brinda servicios de instalación y mantenimiento integrales para ayudarte a maximizar el rendimiento de tu inversión.

Our End-to-End ZLD Services Include:

🛠️ Turnkey Installation

From site assessment and system design to procurement and commissioning, we manage the entire installation process to deliver a fully functional Zero Liquid Discharge Plant ZLD tailored to your facility’s needs.

🔧 Customized System Integration

Our experts design ZLD solutions that integrate seamlessly with your existing water treatment infrastructure, ensuring smooth operation and energy efficiency.

📅 Preventive Maintenance

Regular maintenance checks, calibration, and part replacements help prevent unexpected breakdowns and keep your plant running at peak performance.

📞 24/7 Technical Support

Our dedicated support team is always available to provide remote or on-site assistance, troubleshoot issues, and ensure minimal downtime.

🧪 Performance Optimization

We continuously monitor and fine-tune your system’s performance to enhance recovery rates, reduce operational costs, and maximize ROI.

📚 Operator Training

We provide hands-on training and detailed manuals to equip your team with the knowledge required to operate and maintain the Zero Liquid Discharge Plant ZLD system efficiently. Read More

Why Choose Us

When it comes to Zero Liquid Discharge Plant ZLD Plants, choosing the right partner can make all the difference.

✔️ Expertise and Experience

With years of experience in designing and deploying Zero Liquid Discharge Plant ZLD systems across diverse industries, our team brings unmatched technical know-how and practical insight to every project.

✔️ Customized Solutions

We understand that every facility has unique water treatment challenges. That’s why we tailor our ZLD plants to meet your specific operational needs and regulatory requirements.

✔️ Advanced Technology

We use cutting-edge equipment and proven processes to ensure maximum water recovery, energy efficiency, and minimal environmental impact.

✔️ Quality and Reliability

Our systems are built with premium materials and components to guarantee durability, consistent performance, and minimal downtime.

✔️ Comprehensive Support

Desde la primera consulta y instalación hasta la continua asistencia y soporte técnico, we ofrecen un servicio completo de end-to-end para mantener el funcionamiento óptimo de tu ZLD plant.

✔️ Sustainability Commitment

We are dedicated to helping you achieve your environmental goals by providing solutions that conserve water, reduce waste, and promote responsible resource management. See More

Frequently Asked Questions (FAQs)

A ZLD plant is an advanced wastewater treatment system that recovers nearly all water from industrial effluents, eliminating liquid discharge by using processes like filtration, reverse osmosis, evaporation, and crystallization.

ZLD is crucial for reducing environmental pollution, conserving water resources, and complying with strict government regulations, especially in water-scarce areas.

Industries such as textiles, pharmaceuticals, power plants, petrochemicals, and food processing benefit significantly from ZLD technology to manage wastewater sustainably.

Most ZLD systems recover between 90% to 98% of wastewater, converting it into reusable water for industrial processes, cooling, or other applications.

Traditional treatment reduces pollution but may still discharge liquid effluents, whereas ZLD completely eliminates liquid discharge by recovering and reusing all wastewater.

Installation time varies based on system size and complexity but typically ranges from a few weeks to several months for turnkey solutions.

Operating costs depend on factors like wastewater volume, salinity, and energy consumption, but ZLD systems are designed to optimize energy use and reduce long-term expenses.

Yes, ZLD systems are engineered to treat high-salinity and complex industrial wastewater streams safely and efficiently.

Absolutely. By eliminating liquid waste discharge and promoting water reuse, ZLD technology protects ecosystems and helps industries meet environmental sustainability goals.

Yes, we offer comprehensive installation, maintenance, and technical support services to ensure your ZLD system operates reliably and efficiently.