Zero Liquid Discharge Plant (ZLD)

- Sewage Treatment Plant (STP)

- Effluent Treatment Plant (ETP)

- Common Effluent Treatment Plant (CETP)

- Zero Liquid Discharge Plant (ZLD)

- Rain Water Harvesting System

- Industrial & Commercial RO Plant

- Water Softener

- Demineralization Plant/DM Plant-MB Plant

- Ultrafiltration Plant/UF Plant

- Nanofiltration Plant

- Organic Waste Composting Machine

- Fully Automatic Composter

- Semi Automatic Composter

- Shredder

- Bailing Press Machine

- Solid Waste Recycling Machine

- Waste to Energy

About Us

Manufacture Parts

Wholesale Products

|| Related Parts and Products ||

PRODUCT 1

PRODUCT 2

PRODUCT 3

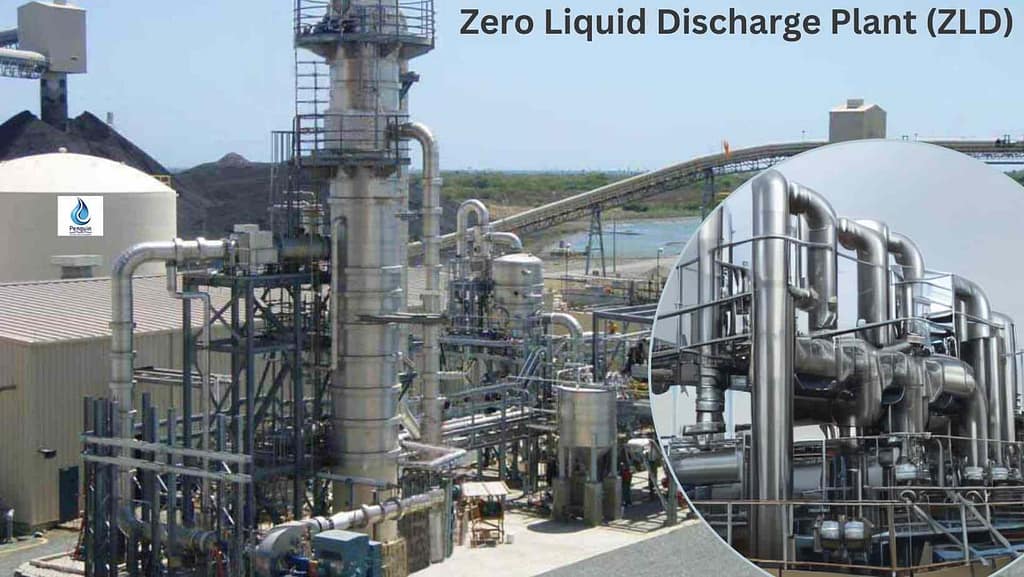

Zero Liquid Discharge Plant (ZLD)

Penguin Water Technologies offers comprehensive thermal & non thermal ZLD solutions to treat wastewater.

Why ZLD is Necessary?

Although ZLD (Zero-Liquid Discharge) is exclusive water treatment process that helps to purify wastewaters and make it safe for the environment. Hence, leaving no discharge at the end of a treatment cycle.

ZLD is an innovative wastewater treatment technique that consists of ultra filtration, evaporation / crystallization, reverse osmosis, & fractional electro deionization.

Moreover, Zero Liquid Discharge technologies assist plants to meet discharge & water recycle requirements. Also, it allows to:

- Treat & recover treasured products from wastewater sources.

- Meet FGD (Flue Gas Desulfurization) and Stringent Cooling Tower Blow down discharge regulations.

- Control the quality of Water that is to be recycled.

- Better Manage produced output water.

What is Included in Zero-Liquid Discharge Treatment System?

The particular components of a Zero-Liquid Discharge treatment system will mainly depend on the capacity of dissolved material existing in the waste, the required flow rate of the system, and what exact contaminants are available.

But generally, a basic ZLD treatment system includes some sort of:

- Chemical Feed: In order to help the precipitation, coagulation, or flocculation of any suspended solids & metals.

- Clarifier And/or Reactor: In order to precipitate out the silica, hardness, and Metals.

- UF (Ultra filtration): For removing every leftover suspended solids & preventing scaling, fouling And/or Corrosion down the treatment line successfully.

- Filter Press: In order to concentrate the secondary solid leftover.

- RO (Reverse Osmosis): It helps to eliminate the majority of dissolved waste solids from water stream in the chief phases of the concentration.

- Crystallizer: Used to boil any residual liquid so you have a dry, firm cake to dispose of.

- Evaporator: For evaporation of access water in the final stages of waste concentration before the crystallizer.

Process Stages of ZLD Treatment

Stage 1-

- Preliminary treatment

- Oil removing process

- Sewage& waste screening process

- Correction procedure of PH

- Effluent mingling

Stage 2-

- Treatment process of primary sludge settling

- Electrochemical coagulation & flocculation process

- Removal process of heavy metals

- Process of removing colour, TSS, and associated COD/BOD

Stage 3-

- Organic treatment process

- Process of sludge treatment

- Treatment process of secondary sludge settling

- Process of removing associated COD/BOD

Stage 4-

- Deepness filtration or polishing process

- Enhancing of SDI, TSS, Colour, Virus, Turbidity, Etc.

Stage 5-

- Removal of TDS.

- Salt Crystallization.

Benefits of Zero Liquid Discharge Plant

ZLD plant technology is increasing day by day as a vital wastewater management method to reduce the water pollution & extend the supply of water.

However, there are some of the chief benefits of the ZLD, they are as follows:

- Reduces wastewater discharge.

- Create at reassured product for sale.

- Maximizes the recovery of water.

- Removing the environmental problems.

- Decreasing the dependence on Local Legislation & Local Water Sources.